New regulations governing the transportation of lead acid batteries (new & used) are set to be adopted around October 2020, in to the Australian Code for Transportation of Dangerous Goods by Road & Rail (ADGC). Originally scheduled for sign off in July, the National Transport Commission (NTC) has chosen to adopt the same Packing Instructions approved in June 2018, by the UN Subcommittee of Experts for the Transportation of Dangerous Goods.

The ADGC is maintained and updated by the National Transport Commission (NTC), with a competent authority in each state responsible for administrating the regulations.

Upon inclusion in edition 7.7 of the ADGC there is a 12 month period for users to adopt the new requirements into their work practices.

The new P801 Packing Instruction (PI) is shown below showing deletions from the current P801. This revised PI now clarifies provisions for the transporting of used batteries in plastics bins or containers and has removed the ‘additional requirements’ in the previous PI.

P801 PACKING INSTRUCTION

This instruction applies to UN Nos. 2794, 2795 or 3028

The following packagings are authorized, provided that the provisions of 4.1.1.1, 4.1.1.2, 4.1.1.6, and 4.1.3 are met:

(1) Rigid outer packagings, wooden slatted crates or pallets.

(2) Wooden slatted crates;

(3) Pallets.

Additionally, the following conditions shall be met:

(a) Batteries stacks shall be in tiers separated by a layer of electrically non-conductive material;

(b) Battery terminals shall not support the weight of other superimposed elements;

(c) Batteries shall be packaged or secured to prevent inadvertent movement;

(d) Batteries shall not leak under normal conditions of transport or appropriate measures shall be taken to prevent the release of electrolyte from the package (e.g. individually packaging batteries or other equally effective methods); and

(e) Batteries shall be protected against short circuits.

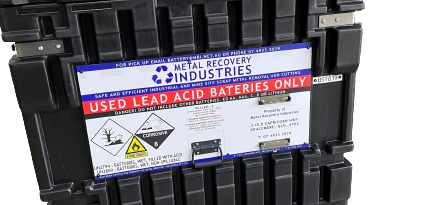

(4)(2) Stainless steel or plastics bins may also be used to transport used batteries.

Additionally, the following conditions shall be met:

(a) The bins shall be resistant to the electrolyte that was contained in the batteries;

(b) The bins shall not be filled to a height greater than the height of their sides;

(c) The outside of the bins shall be free of residues of electrolyte contained in the batteries;

(d) Under normal conditions of transport, no electrolyte shall leak from the bins;

(e) Measures shall be taken to ensure that filled bins cannot lose their content; and

(f) Measures shall be taken to prevent short circuits (e.g. batteries are discharged, individual protection of the battery terminals, etc.).

Download here an extract of the ADGC new P801 Packing Instruction.

A summary of its implications with respect to using the Battery Transport & Storage (BTS) Container, for transporting used batteries can be found on our sister company, Uniseg Products, webpage “revision of UN regulations for transportation of used lead acid batteries“

When using plastic bins, to meet the requirements of item (f) – “Measure shall be taken to prevent short circuits”, see Battery Safety – Reducing Their Fire Risk for information on how to safely stack and transport batteries in plastic bins.