Used Battery Recycling Service for WA Mining Companies & Regional Locations

Battery Rescue’s used lead acid battery collection service delivers compelling benefits to companies that want a safer, more convenient and regulation compliant method for storing and transporting their batteries, while reducing their environmental impact.

It also reduces company’s legal risks by ensuring that consignors are meeting their “chain of responsibility” obligations with respect to Western Australian transportation laws.

A full summary of the benefits of the our battery collection service can be found here.

How It Works

Battery Rescue’s service revolves around the use of its Battery Transport & Storage (BTS) Container which has been purposely designed and manufactured for the storage & transport of used lead acid batteries.

1. We provide your mine site with several BTS Containers, usually at no costs**.

2. When full, simply close the BTS Container and arrange for your transport contractor to deliver to our Perth Yard.

3. At the same time we will arrange for the delivery of the equivalent number of empty BTS Containers to your site, via your transport contractor.

4. When the shipment has been received & weighed, we will email a Recipient Created Tax Invoice (RCTI) and EFT payment at the end of the month.

The Battery Rescue collection service also includes;

- Where preferred, arrange transport documentation and pickup of empty BTS’

- Removal of batteries from the BTS and washing before return

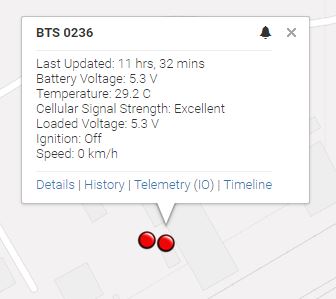

- Containers fitted with relevant Dangerous Goods signage & IoT Device for tracking

- Container & IOT Device Maintenance (no charge)

- Annual report of battery volumes (weight) recycled

** To qualify for the free supply of BTS Containers, clients need to deliver a minimum of 3 Tonnes of batteries per annum per BTS supplied. For sites that don’t meet this requirement, Battery Rescue has introduced a low volume option.

Managing Your Own Fleet of Returnable Containers vs Battery Rescue’s Service

Mining Companies may consider buying & managing their own returnable battery containers, however we believe our battery collection service for Western Australian Mine Sites & Regional locations is a better option, because;

- There is no capital outlay for the client.

- We fit the containers with a 4G enabled IoT device that enables us to manage the containers more efficiently and prevent them being misplaced or lost.

- We empty the containers, neutralise any acid and wash the containers, for return.

- We take care of any container maintenance issues.

The Detail

How Many BTS Containers Will You Be Supplied With

The number of Containers we would recommend initially supplying you is a function of your estimated monthly volumes of batteries and number of locations you would want to place the containers at.

For example, for a single location, with estimated battery volumes of 12 tonne per year or 1 tonne per month, we would recommend supplying you with 2 BTS Containers. This will always ensure there is at least one container on site while the 2nd unit is being transported to Perth and an empty exchange unit returned. We generally allow 2-3 weeks for this process. If you had 2 separate locations on site, where you wanted to install the BTS Containers, then you will need an extra container.

If you can provide us with an estimate of your annual battery volumes and number of locations where the BTS Containers will be installed, we can recommend the number of Containers that should be supplied.

Transport Options

The majority of our mining customers use their contracted transport company, for the shipment of full BTS Containers from their site to our Perth yard and for picking up the equivalent number of empty exchange containers. For most, we arrange the pickup and delivery of the empty BTS Containers, via their contracted transport company, however for some customer’s we delivered the empty containers to their transporter’s Perth yard (customer’s receive less for their batteries with this option).

If your Transporter is going to pickup the empty BTS Containers from our yard and you would like us to arrange this on your behalf, then we need to decide your preferred method. For some of our customer’s we have 3rd party access to their Transporter’s online portal, while others have provided us with a con note book.

Important note: The BTS Container (also known as a UNISEG Container) has been approved as a Type II Dangerous Goods Segregation Device (approval # W008). This means your batteries can be transported with other goods that are specified by the ADGC as being non compatible with Class 8 Corrosives.

Payment for Your Batteries

In most instances we will supply the BTS Containers, at no cost and will even pay you for your batteries. The amount we pay for the batteries is determined by the number of BTS Containers supplied versus your estimated annual volume of batteries (in tonnes). Our current prices can be found on our web page www.batteryrescue.com.au/prices, under the heading “Used Battery Price Schedule for Regional WA”.

The price we pay is also a function of the price set each month by our battery recycler*. Their price in turn fluctuates with changes in the LME price for lead. To ensure transparency to our customers we update our current prices on our web page www.batteryrescue.com.au/prices, whenever there is a change (up or down) of greater than 5%.

* Note that virtually all of Australia’s Lead Acid Battery recycling capacity if located in NSW & Victoria and our current preferred recycler is the Ramcars’ Renewed Metal Technologies.

Invoicing (RCTI)

For most of our customers we generate a recipient created tax invoice (RCTI) and EFT payment for the batteries once the full BTS Container has been delivered to our yard and the weight has been confirmed. Alternatively we can send the weights and rate paid per kg to your accounts department, to issue an invoice to Battery Rescue for payment.

The Use of IOT Devices & Why It’s Important

Operating a “closed loop” container pool, to ensure an empty BTS Container is always availa ble to replace full BTS Containers delivered from a site, can be challenging when dealing with mine sites located in remote areas.

Typically for most of our mine site customers the time taken to transport full BTS Containers from site and return an empty exchange container can be anywhere from 2 – 3 weeks. Combine with the size and complexity of some mining operations, a rotational work force and transport mistakes and you can have your share of logistical headaches.

The availability and affordability of battery powered, 4G Internet of Thing (IoT) devices, which include GPS tracking, has helped eliminate many of these problems and improved the efficiency of operating a ‘closed container pool’.

The IoT devices have enabled tracking of the containers, movement & shock reporting and alerts when containers have entered or exited geofenced areas. These features provide several benefits when managing a closed loop container pool, including;

- Full BTS containers can be identified the moment they are shipped from site, enabling an empty, replacement container to be shipped immediately.

- Identifying and following up on BTS containers that have become misplaced, lost or delayed during transportation.

- Confirmation of containers numbers and where they are.

Battery Rescue uses Uniseg Products’ Uni-Trac browser-based software platform, that delivers and displays the data from the IoT devices in a graphical map display. Uni-Trac also includes features such as alerts for entering and exiting geofenced areas and shock alerts if the BTS Container has been dropped or involved in an accident.

The application of IoT technology significantly simplifies and improves the efficiency of our service to our mining customers.